In the realm of electronics manufacturing, precision and reliability are paramount. As technology continues to advance, the demand for innovative materials that can meet the evolving needs of various industries is on the rise. One such material that has garnered significant attention is gold-tin solder paste. Renowned for its exceptional conductivity, reliability, and versatility, gold-tin solder paste has found applications across a diverse range of industries, from aerospace and automotive to telecommunications and medical devices. In this blog post, we will explore the myriad uses of gold-tin solder paste and its significance in shaping modern manufacturing processes.

Electronics Industry:

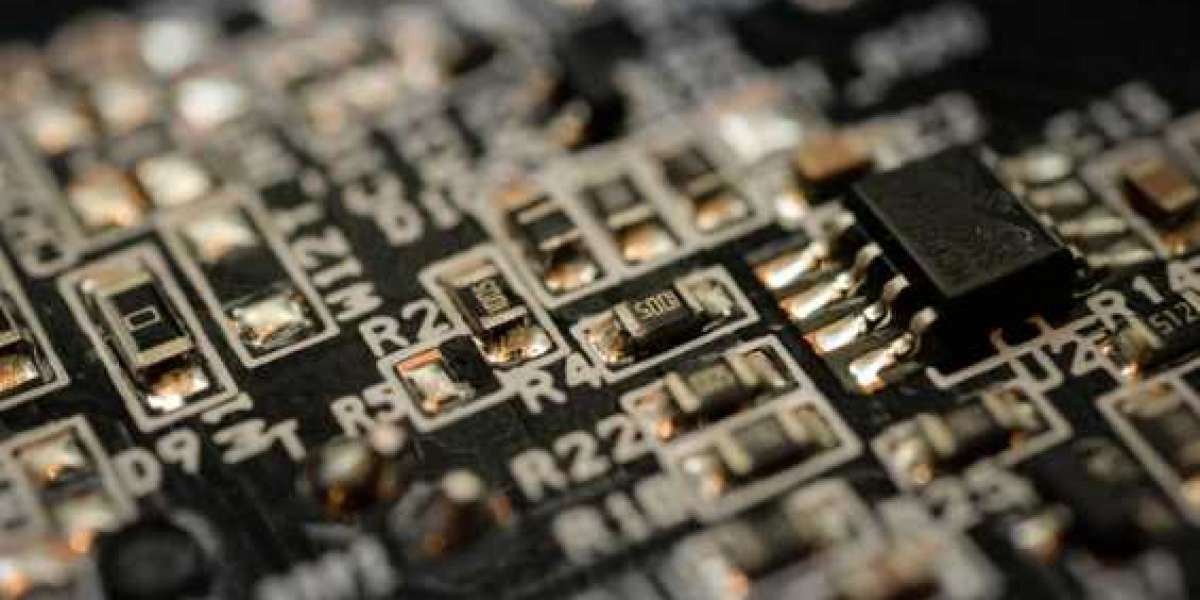

Microelectronics Assembly: Gold-tin solder paste plays a crucial role in the assembly of microelectronic components such as integrated circuits (ICs), microprocessors, and sensors. Its low melting point, excellent wetting properties, and high conductivity make it ideal for bonding delicate components onto circuit boards with precision and reliability.

High-Frequency Applications: In the telecommunications and aerospace industries, where high-frequency performance is essential, gold-tin solder paste shines. Its superior conductivity and stability at elevated temperatures make it well-suited for soldering RF (radio frequency) components, antennas, and microwave circuits, ensuring optimal signal transmission and reliability.

Die Attach: Gold-tin solder paste is widely used in die attach applications, where semiconductor chips are bonded to substrates or lead frames within electronic packages. Its ability to form strong, reliable bonds at relatively low temperatures helps prevent damage to sensitive semiconductor devices, ensuring consistent performance and longevity.

Aerospace and Defense:

Avionics: The aerospace industry demands materials that can withstand extreme temperatures, vibrations, and environmental conditions. Gold-tin solder paste meets these requirements, making it an excellent choice for soldering critical avionics components such as flight control systems, navigation instruments, and communication systems in aircraft and spacecraft.

Military Electronics: Military-grade electronics require robust soldering solutions to ensure reliability in harsh operating environments. Gold-tin solder paste offers exceptional thermal and mechanical properties, making it suitable for soldering components in military vehicles, weaponry, surveillance systems, and communication devices.

Automotive Industry:

Automotive Electronics: As vehicles become increasingly electrified and reliant on sophisticated electronic systems, the demand for reliable soldering materials in the automotive industry continues to grow. Gold-tin solder paste is used in the assembly of automotive electronics, including engine control units (ECUs), safety systems, infotainment systems, and sensors, ensuring optimal performance and durability on the road.

Electric Vehicle (EV) Batteries: With the global shift towards electric mobility, the production of electric vehicle batteries has become a focal point for manufacturers. Gold-tin solder paste is employed in the assembly of battery management systems, thermal management components, and electrical interconnects within EV battery packs, contributing to the efficiency, safety, and longevity of electric vehicles.

Medical Devices:

Implantable Electronics: In the medical device industry, where reliability and biocompatibility are paramount, gold-tin solder paste finds applications in the assembly of implantable electronics such as pacemakers, defibrillators, neurostimulators, and hearing aids. Its biocompatible nature, coupled with excellent electrical conductivity, ensures seamless integration with biological tissues while maintaining optimal device performance.

Medical Instrumentation: Gold-tin solder paste is also utilized in the manufacturing of medical instrumentation and diagnostic devices, including ultrasound machines, patient monitors, and imaging equipment. Its reliability, stability, and ability to withstand sterilization processes make it an indispensable material for soldering critical components in medical devices used in clinical settings.

Alternative Energy:

Solar Photovoltaics: In the renewable energy sector, gold-tin solder paste plays a vital role in the production of solar photovoltaic (PV) modules. It is used to solder solar cells onto conductive substrates, create electrical interconnections between cells, and encapsulate modules for protection against environmental factors. The high conductivity and durability of gold-tin solder paste contribute to the overall efficiency and reliability of solar energy systems.

Energy Storage Systems: Gold-tin solder paste is also employed in the assembly of energy storage systems such as lithium-ion batteries and supercapacitors used in renewable energy storage applications. Its ability to form strong, low-resistance bonds between battery components enhances the performance and longevity of energy storage devices, supporting the transition to a more sustainable energy landscape.

In conclusion, gold-tin solder paste stands as a testament to the ingenuity and innovation driving modern manufacturing across industries. From microelectronics assembly and aerospace applications to automotive electronics, medical devices, and renewable energy systems, its versatility and reliability make it a preferred choice for soldering critical components in a wide range of products. As technology continues to advance and industries evolve, the demand for high-performance materials like gold-tin solder paste will only continue to grow, shaping the future of electronics manufacturing and beyond.