One of those incredible materials, stucco, can be used to design the interior and exterior of a house or other type of establishment. The coatings are available in a range of designs and textures, giving customers the flexibility and durability they need. This material is a solid and affordable way to ensure that your investment will grow over time.

Consistency encourages an improved end product and contributes significantly to performance and outcome quality. Three extremely important measures that must be taken when using this material ensure that it will continue to strengthen over time. The stucco system will seem like snowflakes under a microscope because it binds to the sand molecules. Unexpectedly, it will develop steadily for a further seven days and peak after seven years.

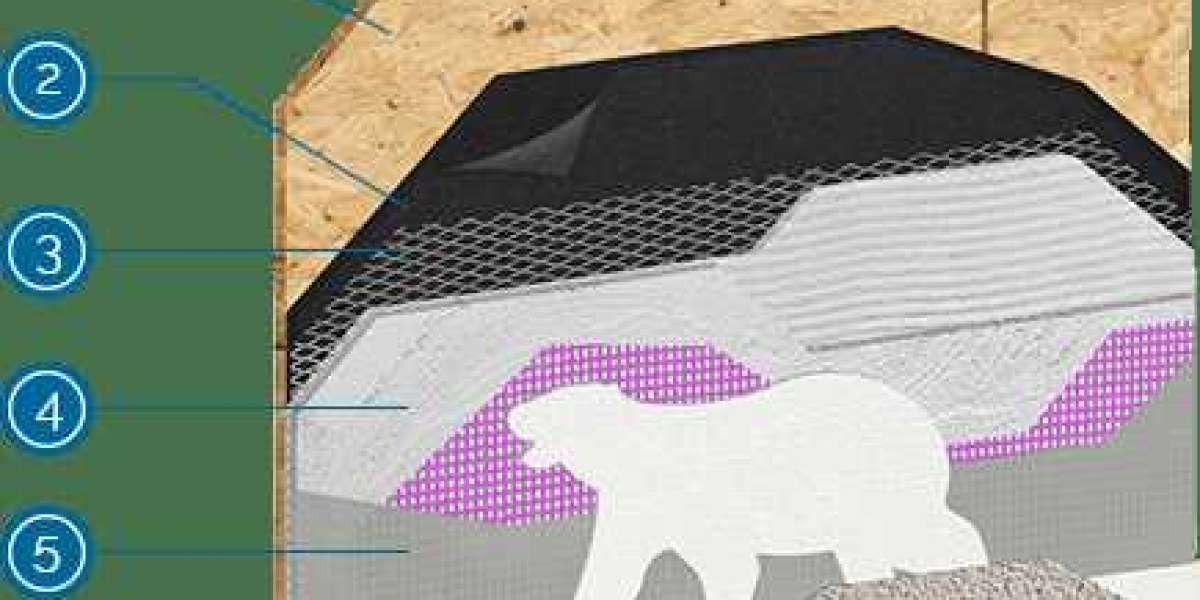

To adequately prepare a well suspended lath material for the three phase application process, outside applications must be put strategically on it. This is the first stage that enables all coatings to attach to the property with the greatest strength possible. After the initial coat, a brown coat is placed and scraped off to provide the illusion of a flat wall that serves as the base for the final product's texture selection.

To guarantee that the material has enough time to cure, there is an industry-standard seven-day waiting period after the second application. After the waiting period is over, the final finish can be safely applied. Water curing is a crucial step in the process because it prevents the wall from drying out too quickly, which could lead to unsightly surface fractures.

The two main components of the brown coating are sand and cement, and it's crucial to use the right mixture to encourage their bonding. The expansion of the cement when water is added makes it much more durable. The ideal combination produces the desired link between these two components, yielding the greatest result for the stucco wall.

There are still three processes with interior installations, however they are significantly different. A fourth step for a polished marble effect is optional. The first surface needs to be flawlessly smooth and free of any flaws, which calls for significant sanding. There are many different colour options, and the finished item is polished with bees wax.

Bees wax is not at all applied to create a matte finish, sometimes known as the Tuscan effect. Choosing your preferred outcome might be difficult because there are so many options to take into account. For individuals who would wish to consider taking on an improvement project, there are many how-to manuals available. Moreover, you can outsource the work to a variety of trustworthy contractors, depending on your budget and level of interest.

Stucco system texas is a fantastic and lovely material to work with and live with since it offers the elegance and old world charm that many customers value. It is a substance that gives the area's inhabitants the impression that they are in a remote location where traditional characteristics are highly valued. Starting your investigation will help you decide which solutions are best for you.