Preservation methods have evolved over time, with freeze drying and dehydration emerging as two prominent techniques for extending the shelf life of various products. In this in-depth exploration, we will dissect the intricacies of freeze drying and dehydration, unraveling the unique processes and outcomes of each method. This guide aims to equip you with a thorough understanding, empowering you to make an informed decision based on your preservation needs.

Understanding Freeze Drying: The Sublimation Symphony

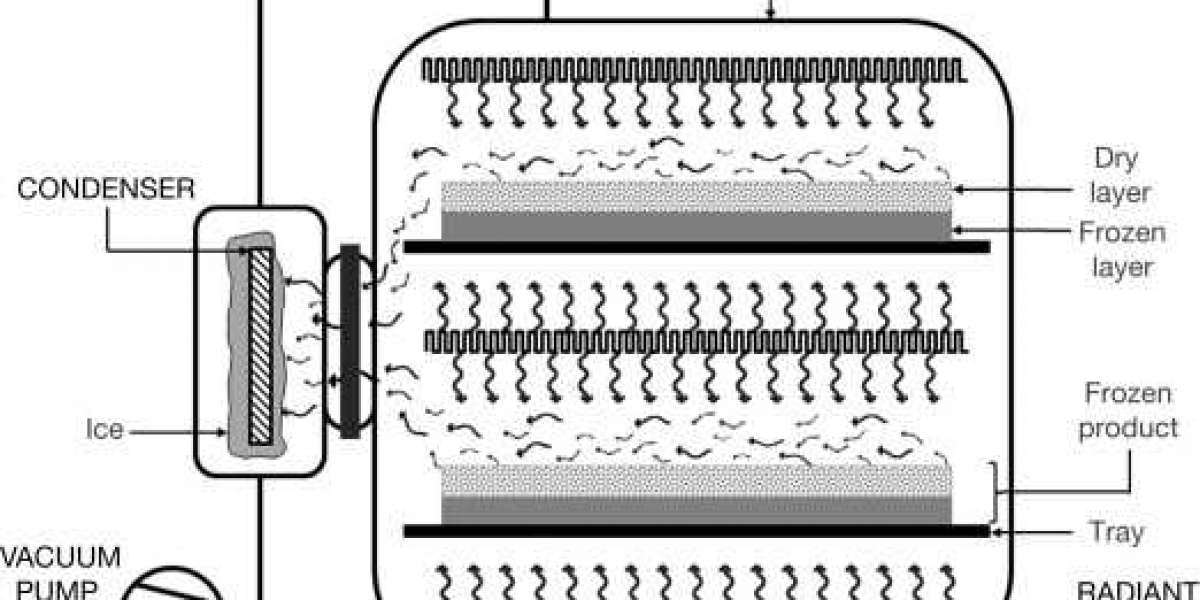

Freeze drying, scientifically known as lyophilization, is a sophisticated preservation process that involves freezing a product and subsequently removing the frozen water through sublimation. Sublimation is a phase transition where a substance transforms directly from a solid to a gas without passing through the liquid phase. In the freeze drying process, the product undergoes ultra-low temperature freezing, followed by the application of a vacuum. This vacuum induces sublimation, causing the frozen water to transition directly into vapor and escape, leaving the product in a dehydrated state.

Pros of Freeze Drying:

- Preservation of Nutritional Value: Freeze drying excels in retaining a higher percentage of the product's original nutritional content compared to certain dehydration methods.

- Maintains Flavor and Texture: The inherent structure of the product is better preserved through freeze drying, resulting in a final product that closely mirrors the original flavor and texture.

- Longer Shelf Life: Products subjected to freeze drying often boast an extended shelf life, a crucial factor for long-term storage.

Cons of Freeze Drying:

- Higher Cost: The initial investment in freeze drying equipment is typically higher compared to dehydration methods, making it a more substantial upfront investment.

- Slower Process: The freeze drying process is inherently slower than dehydration, impacting overall production time.

Navigating Dehydration: The Art of Moisture Removal

Dehydration, alternatively, is a preservation process centered around the removal of moisture from a product, traditionally achieved through the application of heat. Various dehydration methods exist, including air-drying, sun-drying, and specialized dehydrators. In this process, heat reduces the water content in the product, inhibiting the growth of microorganisms and preventing spoilage.

Pros of Dehydration:

- Cost-Effective: Dehydration is often more cost-effective due to simpler equipment and lower operational costs.

- Faster Process: Compared to freeze drying, dehydration is generally a quicker process, facilitating faster production.

- Versatility: Dehydration is a versatile method applicable to a wide array of products, ranging from fruits and vegetables to meat and herbs.

Cons of Dehydration:

- Nutrient Loss: Higher temperatures involved in dehydration can result in some loss of nutritional value in the final product.

- Texture Changes: Dehydrated products may experience alterations in texture, potentially leading to a tougher final product compared to freeze-dried alternatives.

Choosing the Right Method: A Tapestry of Considerations

A. Type of Product:

- Freeze Drying: Best suited for products where maintaining the original texture and flavor is paramount, such as fruits, vegetables, and certain pharmaceuticals.

- Dehydration: Well-suited for a diverse range of products, especially those where changes in texture are acceptable, like dried fruits, jerky, and dried herbs.

B. Nutritional Requirements:

- Freeze Drying: The preferred choice if preserving maximum nutritional content is a priority.

- Dehydration: A viable option for products where some nutrient loss is acceptable, and cost-effectiveness is crucial.

C. Production Scale:

- Freeze Drying: More suitable for smaller-scale productions due to higher equipment costs and longer processing times.

- Dehydration: Efficient for both small and large-scale productions, given its more cost-effective equipment and faster processing.

D. End Use and Consumer Preferences:

- Freeze Drying: The preferred method when the end product needs to closely resemble the original, as seen in gourmet or high-end food applications.

- Dehydration: Suited for products where changes in texture are acceptable, and a more budget-friendly solution is required.

Considering Nutritional Impact: A Closer Look at Health Benefits

1. Freeze Drying: A Nutrient-Rich Option

Freeze drying is renowned for its ability to preserve the nutritional integrity of products to a remarkable extent. The process involves minimal heat exposure, reducing the loss of heat-sensitive nutrients. As a result, freeze-dried foods often retain a higher concentration of vitamins, minerals, and antioxidants compared to their dehydrated counterparts.

2. Dehydration: Balancing Act of Nutrition and Cost

While dehydration may result in some nutrient loss due to the application of higher temperatures, it remains a practical and cost-effective method for preserving a wide range of foods. The nutrient retention varies based on factors such as the type of food, dehydration method used, and the duration of the process.

Evaluating Texture and Palatability: A Sensory Journey

1. Freeze Drying: Preserving Texture and Palatability

Freeze-dried products are known for their ability to maintain the original texture and palatability of the fresh counterparts. The intricate structure of the food is preserved, resulting in a final product that not only looks but also feels and tastes like the original. This makes freeze-dried items particularly desirable for gourmet applications and high-end culinary experiences.

2. Dehydration: Texture Changes and Acceptance

Dehydration, especially when employing traditional methods like air-drying or sun-drying, may lead to changes in texture. Fruits and vegetables, for instance, might become leathery or chewy. However, for certain applications such as jerky or dried herbs, these textural changes are not only acceptable but desired.

Environmental Considerations: The Sustainability Factor

1. Freeze Drying: Energy-Intensive Process

Freeze drying is known to be energy-intensive, primarily due to the low temperatures required during the freezing phase and the energy demands of maintaining a vacuum. While advancements in technology aim to improve energy efficiency, it remains a consideration, especially in the context of sustainable practices.

2. Dehydration: A More Energy-Efficient Approach

Dehydration generally requires less energy compared to freeze drying. Traditional methods like air-drying or sun-drying rely on natural energy sources. Even modern dehydrators are designed to operate efficiently, contributing to a more sustainable approach to food preservation.

Conclusion: A Symphony of Preservation Choices

In the perpetual debate of freeze drying vs. dehydration, there exists no universal answer. The selection between these methods hinges on your specific needs, budget constraints, and the inherent characteristics of the products you aim to preserve. While freeze drying offers superior results in maintaining original texture and nutritional content, it comes with a higher initial cost. On the flip side, dehydration is more cost-effective and faster but may incur some loss of texture and nutrients.

When deciding between freeze drying and dehydration, contemplate your priorities, production scale, and end-use applications. Whichever method you choose, both have etched their effectiveness in preserving a diverse range of products throughout history. Opt for the method that aligns best with your goals, ensuring the sustained quality and longevity of your preserved products.