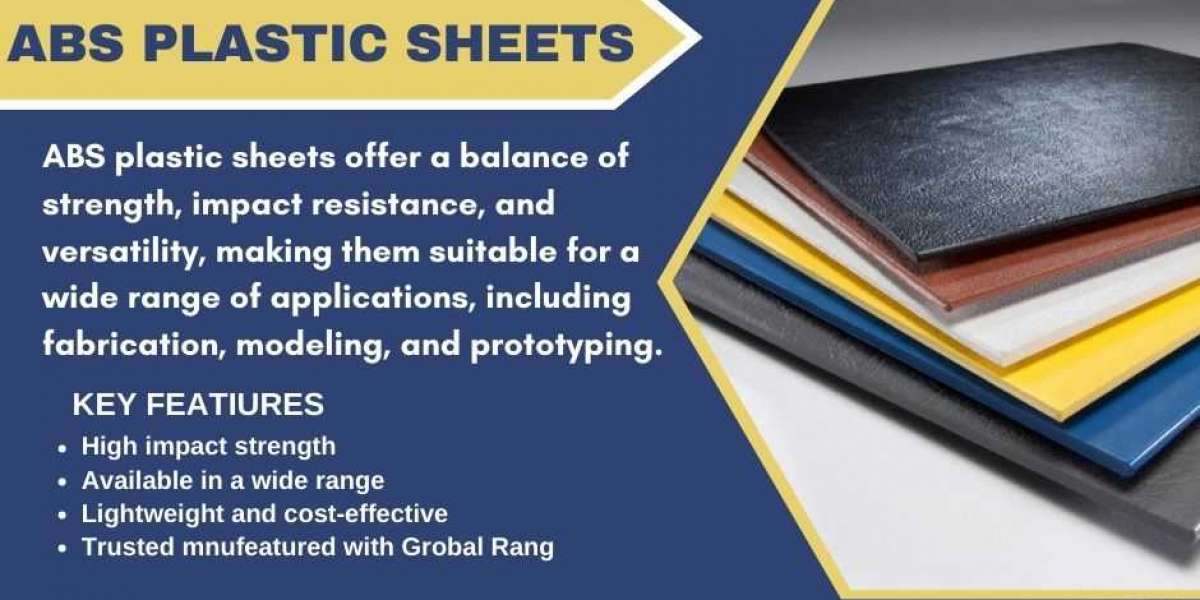

ABS (Acrylonitrile Butadiene Styrene) plastic sheets are renowned for their versatility and durability, making them a popular choice across various industries. Whether you’re involved in manufacturing, construction, or DIY projects, understanding the properties and applications of ABS plastic sheets can help you make informed decisions. This comprehensive guide explores the key features, common uses, and advantages of ABS plastic sheets, and provides insights into finding the right ABS sheet manufacturer in India, including the options available for specific thicknesses like 3/8 inch and 1/4 inch ABS plastic sheets.

What is ABS Plastic?

ABS plastic is a thermoplastic polymer known for its strength, rigidity, and impact resistance. It is created through the polymerization of acrylonitrile, butadiene, and styrene. The resulting material combines the best properties of these monomers, offering a balance of toughness, chemical resistance, and ease of fabrication.

Properties of ABS Plastic Sheets

1. Durability and Strength

ABS plastic sheets are known for their high impact resistance and toughness. They can withstand rough handling and extreme conditions without cracking or breaking, making them ideal for demanding applications. This durability makes ABS a preferred choice for protective covers, housings, and various structural components.

2. Lightweight

Despite their strength, ABS plastic sheets are relatively lightweight compared to metals and other heavy materials. This property simplifies transportation and installation, making it an excellent choice for applications where weight is a critical factor.

3. Easy Fabrication

ABS plastic sheets are easy to cut, shape, and machine, which allows for precise customization. They can be thermoformed, CNC-machined, and glued, offering flexibility in design and manufacturing processes.

4. Chemical Resistance

ABS plastic has good resistance to a wide range of chemicals, including acids, alkalis, and salts. This makes it suitable for use in environments where exposure to corrosive substances is a concern.

5. Surface Finish

ABS sheets have a smooth, glossy finish that can be easily painted or laminated. This aesthetic quality makes them suitable for applications where appearance is important, such as in consumer goods and display panels.

Common Uses of ABS Plastic Sheets

1. Industrial Applications

ABS plastic sheets are used in various industrial applications due to their durability and strength. They are commonly employed in manufacturing machinery parts, machine guards, and equipment housings. The material’s impact resistance and ease of fabrication make it suitable for producing components that must endure heavy use.

2. Construction

In construction, ABS plastic sheets are used for wall panels, roofing materials, and cladding. Their resistance to weathering and impact makes them an effective choice for both interior and exterior applications.

3. DIY Projects

For DIY enthusiasts, ABS plastic sheets are a versatile material for crafting and home improvement projects. They can be used to create custom panels, enclosures, and decorative elements. The ease of cutting and shaping ABS sheets allows for creativity and customization.

4. Automotive and Aerospace

ABS plastic is utilized in the automotive and aerospace industries for components that require high strength and impact resistance. It is used in dashboards, trim pieces, and structural elements where durability is essential.

5. Consumer Products

ABS plastic sheets are found in a wide range of consumer products, including electronic enclosures, kitchenware, and toys. The material’s ability to be molded into complex shapes and its appealing finish make it suitable for various product designs.

Choosing the Right ABS Plastic Sheet Thickness

1. 3/8 Inch ABS Plastic Sheets

3/8 Abs Plastic Sheet are thicker and offer increased strength and durability compared to thinner sheets. They are ideal for applications requiring additional rigidity and impact resistance, such as in heavy-duty machinery guards or structural components.

2. 1/4 Inch ABS Plastic Sheets 4x8

1/4 inch Abs Plastic Sheet 4x8 size, are versatile and widely used in both industrial and consumer applications. This thickness provides a good balance between strength and ease of handling, making it suitable for a range of projects, from construction panels to custom enclosures.

Finding the Right ABS Sheet Manufacturer in India

When selecting ABS plastic sheets, choosing a reputable Abs Sheet Manufacturer in india is crucial for ensuring quality and consistency. Singhal Industries is a leading ABS sheet manufacturer in India, known for its high-quality products and reliable service. They offer a range of thicknesses, including 3/8 inch and 1/4 inch ABS plastic sheets, to meet diverse needs across various industries.

Conclusion

ABS plastic sheets offer a blend of durability, strength, and versatility that makes them a valuable material across various industries. Their properties, such as impact resistance, chemical resistance, and ease of fabrication, make them suitable for a wide range of applications, from industrial components to consumer products.

By choosing the right thickness and sourcing from reputable manufacturers like Singhal Industries, you can ensure that you get high-quality ABS plastic sheets tailored to your specific needs. Whether you’re working on a construction project, a DIY venture, or industrial manufacturing, ABS plastic sheets provide a reliable and effective solution.

Embrace the advantages of ABS plastic sheets and make informed choices for your projects to achieve the best results and performance.

FAQs About ABS Plastic Sheets

1. What are the main properties of ABS plastic sheets?

ABS plastic sheets are known for their durability, impact resistance, lightweight nature, chemical resistance, and smooth surface finish. These properties make them suitable for a wide range of applications.

2. What are the common uses of ABS plastic sheets?

ABS plastic sheets are used in industrial applications, construction, DIY projects, automotive and aerospace industries, and consumer products. Their versatility makes them suitable for various applications that require strength, impact resistance, and aesthetic appeal.

3. How do I choose the right thickness for my ABS plastic sheet?

The choice of thickness depends on the application and requirements. Thicker sheets, such as 3/8 inch, offer greater strength and durability, while thinner sheets, such as 1/4 inch, are more flexible and easier to handle. Consider the specific demands of your project when selecting the thickness.

4. Where can I find reliable ABS plastic sheet manufacturers in India?

Singhal Industries is a reputable ABS sheet manufacturer in India, offering a range of products and thicknesses to meet various needs. They are known for their high-quality ABS plastic sheets and reliable service.

5. Are ABS plastic sheets easy to fabricate?

Yes, ABS plastic sheets are relatively easy to cut, shape, and machine. They can be thermoformed, CNC-machined, and glued, providing flexibility in design and manufacturing processes.