In the realm of civil engineering and infrastructure development, the quest for reliable, cost-effective solutions to enhance stability and longevity is perpetual. Polyester Geogrids have emerged as a pivotal technology in this pursuit, offering a robust means to reinforce soil structures, prevent soil erosion, and support various construction projects. As a leading manufacturer of flexible packaging products, Singhal Industries introduces Polyester Geogrid Solutions, designed to meet the demanding needs of modern infrastructure development.

Understanding Polyester Geogrids

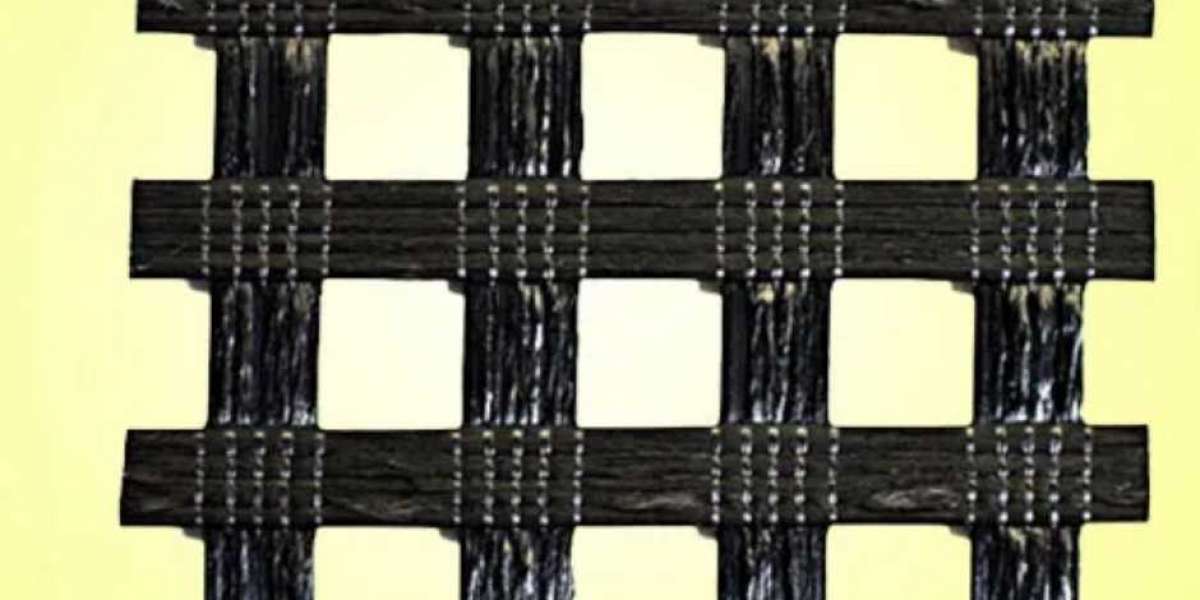

Polypropylene geogrid suppliers are engineered materials constructed from high-tenacity polyester yarns, woven or knitted together and coated with polymers for added strength and durability. These grids typically feature a grid-like pattern that provides tensile reinforcement when embedded within soil or aggregate layers. The primary function of Polyester Geogrids is to distribute loads over a wider area, improve soil stability, and enhance the structural integrity of roads, embankments, retaining walls, and other civil engineering applications.

Key Features and Benefits

1. High Tensile Strength

Polyester Geogrids are renowned for their exceptional tensile strength, which allows them to withstand high loads and distribute stresses effectively. This characteristic is crucial in reinforcing weak soils, stabilizing slopes, and improving the overall performance of infrastructure projects.

2. Durability and Chemical Resistance

Manufactured using polyester, these geogrids offer inherent durability and resistance to chemical degradation. They remain unaffected by exposure to harsh environmental conditions, including UV radiation, moisture, and varying temperatures, ensuring long-term reliability in diverse applications.

3. Flexible and Easy to Install

Despite their robust construction, Polyester Geogrids are lightweight and flexible, facilitating easy handling, transportation, and installation on-site. Their flexibility allows them to conform to irregular surfaces and contours, optimizing efficiency during construction.

4. Enhanced Soil Reinforcement

By interlocking with soil particles, Polyester Geogrids create a stable composite structure that improves bearing capacity and reduces settlement. This reinforcement technique not only minimizes construction time but also lowers maintenance costs over the lifespan of the project.

Applications in Infrastructure Development

Polyester geogrid Manufacturers Solutions from Singhal Industries cater to a wide range of infrastructure applications, including:

- Road Construction: Enhancing the stability of base and sub-base layers, reducing rutting and extending pavement life.

- Retaining Walls: Providing structural support and preventing soil erosion behind retaining walls.

- Embankments and Slope Stabilization: Reinforcing soil slopes to prevent landslides and erosion.

- Foundation Support: Distributing loads effectively under foundations and improving soil bearing capacity.

Environmental and Economic Benefits

Beyond structural advantages, Polyester Geogrid Solutions contribute to sustainable development practices:

- Reduced Material Usage: Optimizing soil conditions reduces the need for additional fill materials.

- Long-Term Performance: Enhancing durability and reducing maintenance requirements lower lifecycle costs.

- Environmental Preservation: Minimizing soil erosion and stabilizing slopes mitigate environmental impact during and after construction.

Conclusion

Polyester geogrid india Solutions from Singhal Industries represent a cornerstone in modern infrastructure development, offering superior strength, durability, and versatility. Whether applied in road construction, slope stabilization, or foundation support, these geogrids ensure enhanced stability and longevity of civil engineering projects. Embrace the future of infrastructure stability with Singhal Industries' Polyester Geogrid Solutions, designed to meet the evolving demands of sustainable and resilient construction practices.

Contact us today to learn more about how Polyester Geogrids can elevate your infrastructure projects and ensure lasting performance.

FAQS

1. What are Polyester Geogrid Solutions?

Polyester Geogrid Solutions are advanced materials made from high-strength polyester fibers woven or knitted into a grid-like structure. They are designed to reinforce soil, enhance stability, and improve the performance of infrastructure projects such as roads, retaining walls, and embankments.

2. How do Polyester Geogrids enhance infrastructure stability?

Polyester Geogrids distribute loads more effectively across soil layers, reducing settlement and improving bearing capacity. By reinforcing weak soils and preventing erosion, they enhance the overall stability and longevity of civil engineering structures.

3. Where are Polyester Geogrid Solutions commonly used?

Polyester Geogrids find applications in various infrastructure projects, including:

- Road construction and rehabilitation

- Retaining walls and bridge abutments

- Slope stabilization and embankments

- Foundation support and pavement reinforcement

4. What are the key benefits of using Polyester Geogrids?

Key benefits include:

- High tensile strength for effective load distribution

- Durability and resistance to environmental factors

- Easy installation and flexibility for diverse site conditions

- Cost-effectiveness by reducing construction time and maintenance

5. Are Polyester Geogrid Solutions environmentally friendly?

Yes, Polyester Geogrids contribute to sustainable construction practices by minimizing the need for additional fill materials and reducing soil erosion. Their long-term durability also lowers lifecycle costs and environmental impact compared to traditional construction methods.